Raised Floor System

Access floor system, as known as a raised floor, is an innovative lifted floor system constructed on top of a solid concrete slab or substrate. It furnishes an empty space as a tunnel for electrical and building services. It is widely applied in heating ventilation and air conditioning, telecoms and data cabling, electrical power settings and so forth. The most common usage for raised floor systems in Hong Kong is in office areas and server rooms.

Office raised access floor is mainly divided into a calcium sulphate panel and bare panel. They are both suitable in office installation. Calcium Sulphate panels are manufactured by PVC veneer or HPL with aluminium skin which is anti-static and high resistance. Apart from calcium sulphate panel, the major element of forming bare panels is steel which is fully equipped with anti-impact ability by in-filled cementations. Also, it has an excellent coating surface to mount easily and perform wearing resistance.

Office Raised Access Floor Systems – A Flexible Solution

Appearance and accessibility of installation are important issues for the office interior decoration or refurbishment. Raised floor panels are independent products that can be installed and removed easily. When there is an imperative decision of remodelling an office area, it enables flexible solutions without altering the original appearance. Air-conditioning equipment, wiring and power plugs are installed underneath the raised floor panel replacing the overhead wiring systems on the ceiling. Better surface covering enhances the office’s aesthetic. Also, no damage on the wall since screeding is not needed. Ladders are also not necessary for repairs, so maintenance costs are undoubtedly saved. Access floor systems are durable and achieve the goal of sustainable development for the future.

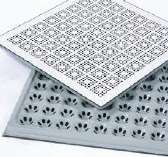

Anti-static Raised Floor Systems for Hong Kong

HPL Panel and perforated panel are classified as an anti-static raised floor system. HPL panels are made by modern laminate technology, as a result of tropical layers on panels which make these panels advantageous. Apart from the increase of the stability, it also has scratch and stain resistance properties that require very low maintenance. On the other hand, perforated panels are made with either high-wear anti-static HPL or conductive PVC top-finished. Perforated rate varies from 17% to 50%.

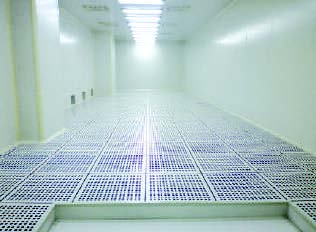

Ideal in Communications and Technology Settings

With high standard concentrated loading of mechanical technology in a hermetic data centre, it faces a constant problem of overheating. Maintaining proper temperature among servers and efficient ventilation management from sub floor areas are required. Thus, installing a raised floor system is conducive to thermal impact.

Meanwhile, they are designed specifically to increase the efficiency of communications, computing technology accessibility. It has the advantage of consolidating a huge amount of data cabling and telecoms under the raised floor panel in uncluttered order. Since all the cables are placed under the raised floor by keeping away from accumulating dust, the hazard of computing technology’s failure will decrease correspondingly. It ensures the stability and safety of the data centre.

Although applying a raised floor system is simple apparently, the following installation essentials need to be considered. Recording the data of height between substrate and the panel, covering and other supporting materials are required. Meanwhile, level measure is to make sure the surface of the subfloor is even and fixed with prepared equipment before beginning execution. It avoids irregular and unstable access floors caused by residues, depressions and fragmentation on the subfloor. The aforementioned points facilitate the whole process of building up the access floor at a specific location or setting.